“All truths are easy to understand once they are discovered; the point is to discover them.”

Galileo Galilei – Italian astronomer & physicist (1564 – 1642)

in collaboration with: –

Objective: Investigate the effect of high temperature and fire on the mechanical characteristic of UHP-FRC as a result of physical processes and chemical reaction

in collaboration with: Prof. S. El-Tawil, Prof. A.E. Naaman, University of Michigan

Objective: Investigation of strain rate dependent tensile characteristic of strain-hardening UHP-FRC

| a) Test-Setup b) Specimen c) Multiple Cracking | ||

| Fig. 5 – Tensile testing under various strain-rates |

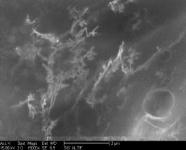

Nano-Engineering Ultra-High Performance Concrete with Multi-Walled Carbon Nanotubes

in collaboration with: Prof. K. Loh, UC Davis

Objective: Enhancement of mechanical performance and sensing characteristic of UHP-FRC through the inclusion of multi-walled carbon nanotubes (MWNT) in the mix design

| a) UHPC b) Well dispersed MWNT c) Adding of MWNT |

| Fig. 4 – UHPC – MWNT Composite Design |

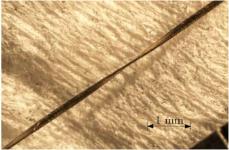

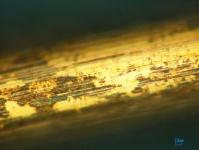

Tensile Behavior of Ultra High Performance Fiber Reinforced Concrete (UHP-FRC)

in collaboration with: Prof. A.E. Naaman, Prof. S. El-Tawil, University of Michigan

Objective: Enhancement of tensile behavior of UHP-FRC through ternary design approach: 1) matrix optimization, 2) usage and utilization of high strength fiber, 3) tailoring of matrix-fiber interface properties

| a) Cementitious Composite b) Matrix c) High Performance Fiber d) Fiber-Matrix-Bond |

| Fig. 3 – UHP-FRC Material Composite Design |

Ultra High Performance Fiber Reinforced Concrete (UHP-FRC) – Influence of Fiberorientation

in collaboration with: Prof. N.V. Tue, Graz University of Technology, Austria, Prof. G. Parra-Montesinos, Univ. of Michigan

Objective: Experimentally influence, obtain and analyze the fiber orientation of UHP-FRC structural elements to understand and evaluate the fiber orientation dependent material characteristic

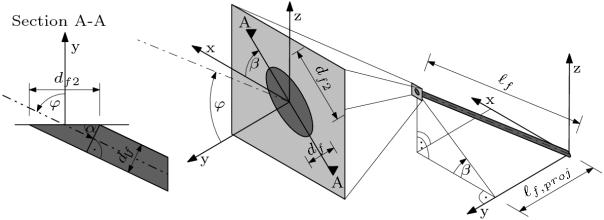

| a) digital image b) after analyzing c) geometric aspects of fiber orientation |

| Fig. 2 – UHP-FRC cross-sectional fiber orientation |

Ultra High Performance Concrete (UHPC) – Matrix Optimization

in collaboration with: Prof. A.E. Naaman, Prof. G. Parra-Montesinos, Univ. of Michigan

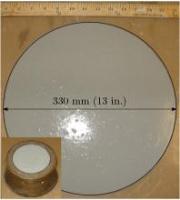

Objective: UHPC design by optimizing the mixture packing density through slump cone tests without the need of special treatment such as heat curing, pressure and/or extensive vibration

| a) Paste spread b) UHPC spread c) Debris of 6 specimens |

| Fig. 1 – Fine-tuning of UHPC material design by spread tests |